Multi-lane Center-Seal Packaging Machine for Sauces DL-JL-B

Multi-lane Center-Seal Packaging Machine for Sauces DL-JL-B

Contact us for price

Location:Ontario, CA

or

Call +1(626)3202070

Description

Product Introduction

- Plunger Pump Quantitative Filling System:The sauce filling system features a high-precision gear pump, designed with CNC-refined SUS316L stainless steel for superior precision and versatility. Each row is driven by an independent bus servo motor to control the quantitative filling. The system is equipped with an insulated double-layer hopper that supports essential functions such as two-way mixing and automatic feeding. It also includes a general cleaning device as standard, with the option to integrate a CIP cleaning system for enhanced sanitation.

- Easier Maintenance:All parts in contact with the packaged material are designed for easy disassembly and reinstallation, allowing for quick and efficient maintenance.

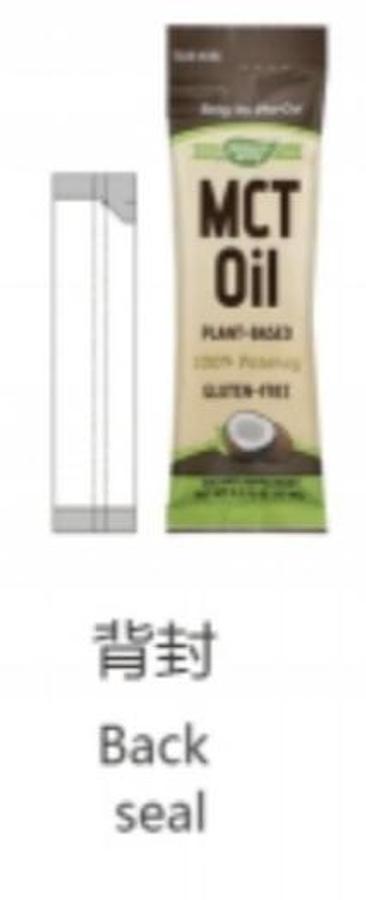

- Vertical Sealing Features:The vertical sealing device delivers excellent longitudinal sealing performance. It can be opened from the middle to both sides for easy access and maintenance, ensuring smooth operation.

Applications

- This product is ideal for packaging various solid-liquid pastes, including sauces, seasonings, hot pot bases, ketchup, honey, jams (with residues), creams, facial cleansers, shower gels, and more.

- It is widely used in industries such as cosmeceuticals, food, pharmaceuticals, healthcare products, and others.

Key Features

- Efficient Anti-Fingerprint: The device is easy to clean, maintaining a clean surface free of fingerprints.

- Automatic Deviation Correction: The film frame and film tension control system ensure stable and accurate bag-making, preventing misalignment.

- System Configuration: Equipped with a programmable bus system and bus servo for fast response and increased precision.

- Color Mark Control: A color sensor detects the color punctuation points on the packaging film, ensuring pattern integrity throughout the process.

- Industry 4.0 Compatibility: The machine can be connected to SCADA and MES systems, meeting the digital factory requirements of Industry 4.0.

- Multiple Operation Languages: Supports 12 commonly used languages for easy operation, with equipment fault prompts and self-diagnosis functionality.

- Safety Certification: Compliant with GMP production standards. The entire machine is CE certified, and the electrical configuration is CUL certified.

- Food-Grade Stainless Steel: Constructed from SUS304 stainless steel, with parts in direct contact with the material made of SUS316 for enhanced safety and hygiene.

- Advanced Temperature Control: Features a bus-type temperature module with independent temperature control. Temperature accuracy is maintained within ±0.1°C, and settings are controlled via the touch screen.

- Automatic Film Detection: The system automatically detects film breakage or shortage, with an alarm and shutdown function. It also includes a film roll correction and docking device for smooth operation.

Specifications

| Manufacturer | Hongda |

| Model | DL-JL-B |

| Condition | New |

| Stock Number | 12 |

| Number of Lanes | 2 / 4 / 6 / 8 / 10 Lanes |

| Measuring Method | Gear Pump;Piston Pump |

| Bagging Speed | 20–80 bags/min |

| Bag Size (W × L) | 0.6–2.0 in × 1.6–7.9 in |

| Cut Type | Round Corner Cut;Straight Cut;Serrated Cut |

| Power Supply | 200-230Vac,3P,50/60Hz,11KW |

| Air Pressure / Air Consumption | 87–116 psi / 2.8–3.5 CFM |

| Film Thickness | 2.4–4.0 mil |

| Film Materials | OPP/CPP, OPP/PE, BOPP/VMPET/PE |