Powder Filling Machine HA-LX

Powder Filling Machine HA-LX

Contact us for price

Location:Ontario, CA

or

Call +1(626)3202070

Description

1.Overview

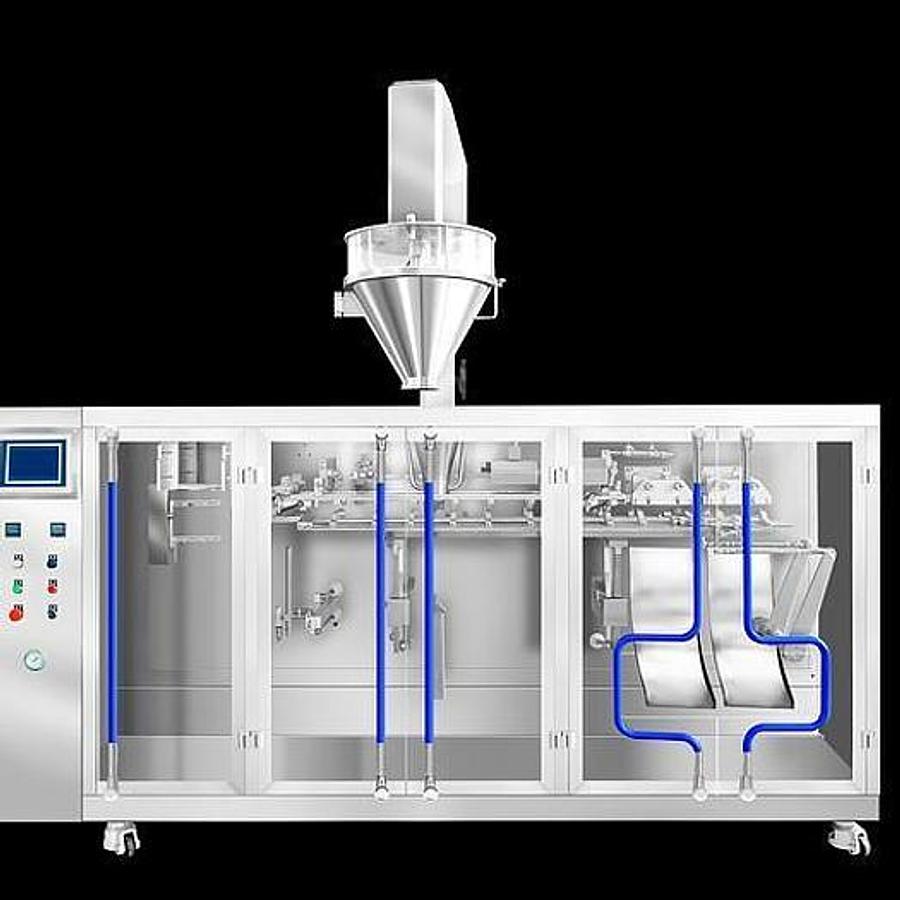

- The screw-type powder filling machine is a specialized packaging equipment designed to accurately measure and fill powdered products into containers such as bottles, bags, or cans.

- It utilizes a rotating screw mechanism for precise dosing and is suitable for industries such as food, pharmaceuticals, chemicals, and cosmetics.

2.Core Features

- Screw Filling System

- Uses a screw feeder (screw auger) for measurement and filling.

- Adjustable screw speed and pitch enable both volumetric and weight-based accurate filling.

- High Precision Filling

- Suitable for powders with either good or poor flowability.

- Some models are equipped with weighing sensors, with an accuracy range of ±0.5% to ±1%.

- Wide Applicability

- Can handle a variety of powders, such as spices, flour, milk powder, protein powder, and pharmaceuticals.

- The hopper and screw size are adjustable, allowing compatibility with different container types.

- Waste Reduction

- Anti-drip design prevents powder spillage.

- Some models include vibration or agitation devices to prevent powder caking.

- Automation Options

- Semi-automatic (manual feeding) or fully automatic (integrated with a production line, including conveyors and sealers).

- PLC control with a touch-screen interface for easy operation.

- Compliance & Safety

- Made of food-grade stainless steel (SS304/SS316), meeting GMP, FDA, or CE standards.

3.Applications

- Food Industry: Milk powder, coffee powder, seasonings, flour, sugar, etc.

- Pharmaceutical Industry: Pharmaceutical powders, health supplements, active pharmaceutical ingredients (APIs).

- Chemical Industry: Laundry powder, pigments, additives.

- Cosmetic Industry: Talcum powder, loose powder, powdered cosmetics.

Specifications

| Manufacturer | Hongda |

| Model | HA-LX |

| Year | 2025 |

| Condition | New |

| Stock Number | 88 |

| Filling machine | Screw-type Powder Filling Machine |

| Hopper Capacity | 6.6USG/13USG |

| Weighing Range | 0.35–1.76 oz/1.76–3.53 oz/3.53–17.64 oz |

| Dosing Accuracy | ±0.035-0.176 oz |